Table Of Content

DFM reduces the requirement for expensive production changes by preventing errors and discrepancies through early resolution of manufacturability concerns. The goal of design for manufacturing (DFM) is to optimize a product’s design to save costs, improve efficiency, and streamline the manufacturing process. It entails taking production capabilities and limitations into account from the very beginning of the design process to ensure that the product can be manufactured effectively and inexpensively. Design for Manufacturing or Design for Manufacturability (DFM) is the optimisation of a part, product, or component’s design, to create it cheaper and more easily. DFM involves efficiently designing or engineering an object, generally during the product design stage, when it is easier and less expensive to do so, to reduce manufacturing costs.

Elevate Manufacturing Workflows With 3D Printing

Designing medical devices with smooth, easy-to-clean surfaces to meet hygiene requirements.Ensuring ergonomic designs for user-friendly and efficient operation by medical professionals. Each component in the product must be able to perform in these conditions. The IoT, AI and ML are just a few of the new technologies that will propel DFM into the future and bring about Industry 4.0 practices.

What are the Principles of DFM?

Fiber-reinforced plastics (FRPs) are composite materials made up of a polymer matrix reinforced with fiber. The unique combination of physical properties found in FRPs can bring significant... Residential construction requires different products from those used in commercial buildings. Even though residential sub-divisions don’t usually have skyscrapers, home project builders,...

Understanding the Role of DFM in Product Development

Where applicable, it is recommended to use non-destructive testing methods since the test piece will still be fully operational and intact even after completing the testing process. Product design is probably one of the key factors that has significant implications on the feasibility of the operation. An efficient design can cut down costs and lead times remarkably, sometimes through seemingly minor modifications. This is why designers need DFM tools to analyse the effects of their design choices on production. Leveraging the digital enterprise streamlines these validation processes and puts more capability in the hands of designers for the product’s sustainability.

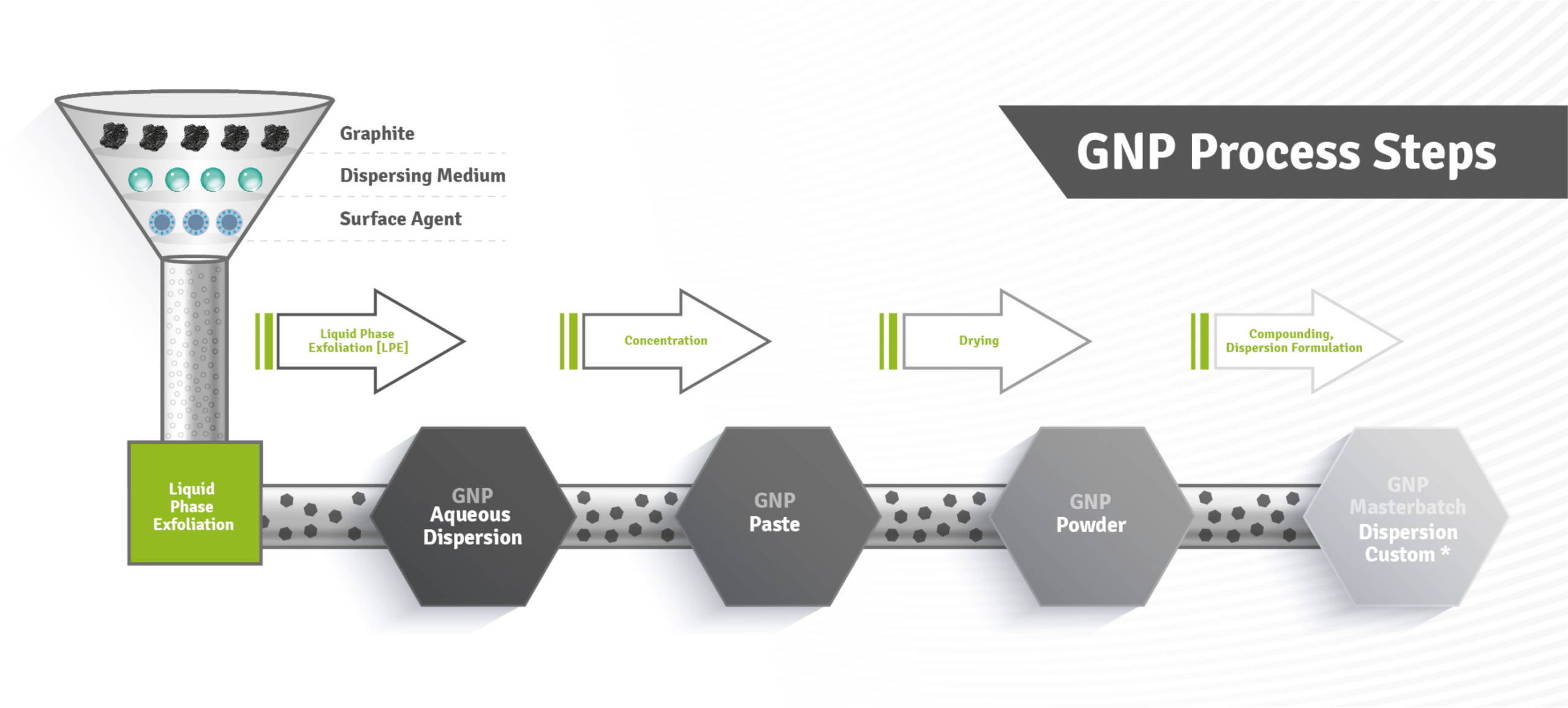

Material form

Reliability principles require designers to identify the cause of each failure and work to minimize that risk so the failure doesn’t occur within the product’s lifecycle. DFM principles recommend compliance testing on a design before it enters mass production, as correcting these problems is far more expensive at the end of product development. This type of testing should also be non-destructive to ensure the test piece is fully functional afterward.

Leveraging Simulation and Analysis Tools for DFM

If that’s the case, then you want to make sure you are adhering to the best design practices possible. There is a huge variety of materials available for manufacturing products, creating a strong opportunity to optimize material selection. For example, an electronics enclosure can be manufactured using multiple techniques including machining, injection molding, and 3D printing. The DFM experts weigh the pros and cons of each process in light of the design and suggest the most viable one to the design and production teams. By further integrating DFM with Industry 4.0 technology, we'll continue to see transformations in manufacturing processes.

Serviceability with DFM Principals

Solar SunShot manufacturing program enters design phase – pv magazine Australia - pv magazine Australia

Solar SunShot manufacturing program enters design phase – pv magazine Australia.

Posted: Mon, 22 Apr 2024 23:53:46 GMT [source]

Moreover, material selection is much more than about part functionality alone. Additionally, some materials have a negative environmental impact and can contribute to violations of carbon footprint goals. The job of design for manufacturability experts is to find ways to optimize these processes. At first, they look at the design and see if the design engineers have made the right process selection. With the key objectives of cost reduction, quality enhancement, and sustainable waste reduction in mind, engineers look to improve the following five areas of a manufacturing process during DFM analysis.

They also make each and every piece in their own Sunset Park, Brooklyn, workshop. Yet another veteran of Site Unseen, Voggegut/Kraft's sculptural furniture designs are as hefty in size as they are in forethought. And now, some of her items of furniture are available at Urban Outfitters. To succeed, businesses need to move away from siloed knowledge of their products and processes toward collective intelligence to make better design decisions. 3D printing technology simplifies the creation of prototypes, so designers can have high-fidelity, functional parts within hours at a fraction of the cost of a traditional prototype. Watch our webinar to learn how engineers at Formlabs used desktop 3D printers in production, from prototyping for manufacturability to printing functioning end-use parts used on the line.

FACTORS THAT AFFECT DFM

This can happen when DFM teams use methods like topology optimization to suggest weight reduction or a change in the preferred manufacturing technique. Now that we have a high-level overview of design for manufacturing, let us get into the nitty-gritty details of it from an engineering point of view. A central element of DFM analysis is to identify all areas of waste and optimize the process to eliminate as much of it as possible. Design for manufacturing plays an important role during the designing phase of the product, this is when essential production-related aspects of the product are defined.

The traditional mindset of using wood, steel and aluminum in the architecture and construction sectors is fast being replaced with the use of new,... Organizational culture and leadership play a crucial role in the successful implementation of DFM. Companies with a culture that values collaboration and continuous improvement are more likely to implement DFM successfully.

Your goal is to prototype and test the design to validate the function and performance. Get into production faster with Teamcenter manufacturing process planning and data management. Collaborate instantly and securely to optimize part production and assembly operations. Design for manufacturing and assembly (DFMA), is an engineering methodology that focuses on simplifying the design of a product to improve ease of manufacture and efficiency of assembly.

In this video, you’ll hear how Spirit Aerosystems uses aPriori’s manufacturing insights to evaluate parts for cost drivers and to identify cost reduction opportunities. Discover how Spirit Aerosystems used aP Pro to support the development of internal fabrication discrete parts estimates. The right manufacturing cost modeling software makes it far easier to generate detailed insight into cost structure that can impactfully inform supplier negotiations.

While there may be a good reason for this, it may also identify a design flaw that, if corrected, could dramatically accelerate the manufacturing process and drive down cost accordingly. While the principles are a great start, digital manufacturing simulation is the key to unlocking the analytical problem at the heart of DFM. Your goal is to decide on the optimal manufacturing process based on factors like cost, production volume, and product factors.

No comments:

Post a Comment